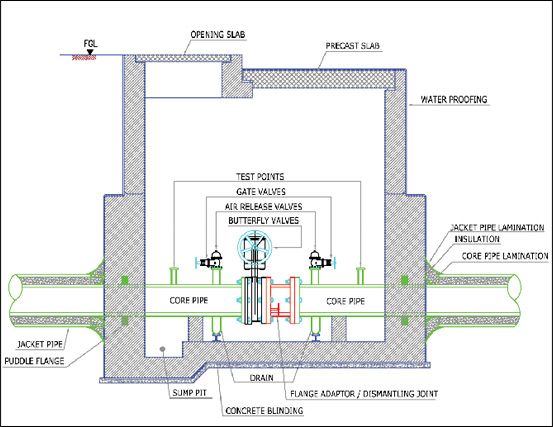

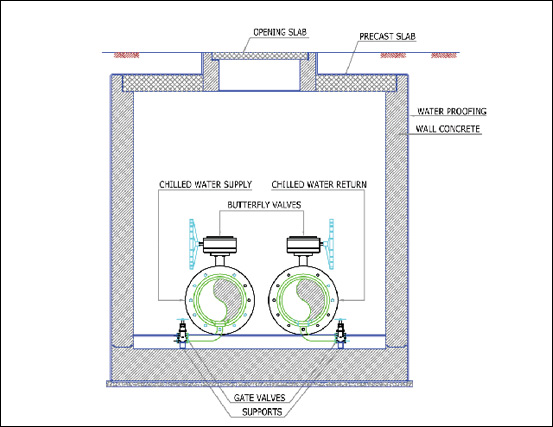

Valve chamber |

|

The figure shows a typical valve chamber constructed for the GRP chilled water supply and return network. These valves chambers are also called isolation valve chambers as it can be used for isolating different consumers of chilled water in case of any shut down or maintenance works. GRP pipes are installed with puddle flanges embedded in the concrete which acts as a thrust block and absorbs the longitudinal force developed in the pipeline. The valve chamber consists of equipments like butterfly valves, Gate valves, Air release valves, Flange adaptors, Dismantling joints and test points for the proper functioning of the piping system. Gate valves are used to drain the line after closing the butterfly valves and air release valve enables the air bubbles entrapped inside the pipe line to escape to the atmosphere. The structural design of the valve chamber will vary according to the pipe size, Air release valves, Flange adaptors, Dismantling joints and test points for the proper functioning of the piping system. Gate valves are used to drain the line after closing the butterfly valves and air release valve enables the air bubbles entrapped inside the pipe line to escape to the atmosphere. The structural design of the valve chamber will vary according to the pipe size, internal pressure, valve chamber height, soil bearing capacity and water table in the trench. Proper sealing is done at the area of pipe penetration through the valve chambers. Cladding is done for all the valves and air vents inside the chamber in order to minimize the heat gain. Flange adaptors or telescopic dismantling joints shall be installed together with the butterfly valve, if design specifies, to make the dismantling of butterfly valves easy in future, in case of any shut down or maintenance work. |

|

|