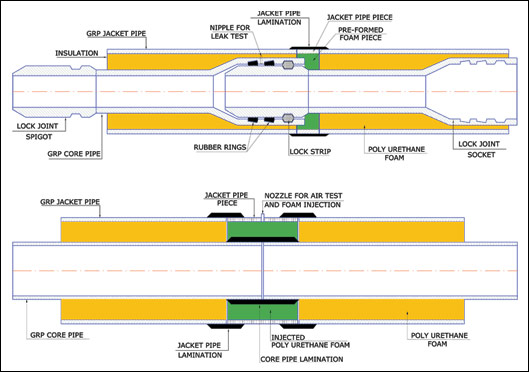

Lock Joint

This is a restrained joint system which combines the advantages of both glue joint and flexible joint. The integral socket and spigot ends are joined together as in the drawing. The hydraulic sealing is performed by elastomeric rubber rings, installed in circumferential groove on the integral socket. The locking device, which provides longitudinal thrust restraint is inserted into a groove through an opening and can be removed to disassemble the joint at some later stage. Shear resistant plastic material is used for the locking strip. A nipple is fixed between the rubber rings, which is used for conducting a hydraulic test which ensures the rubber rings are installed leak proof. The gap between the two pipes is filled with a pre-formed piece of poly urethane foam. Either a small strip of jacket pipe is inserted and laminated or wrapping is done directly on the foam piece to complete the jacket pipe installation.Pre-insulated lock joint pipe is avilable for pipe size 100mm to 1000mm

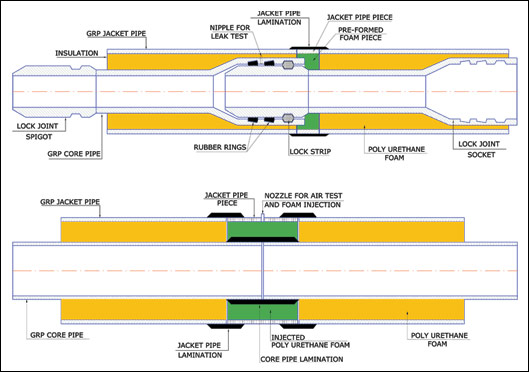

Lamination

Joint

This is a restrained joint system used for joining plain end pipes which consists of overlapping layers of fiberglass reinforcement thoroughly impregnated with the resin to achieve the specified width and thickness. It provides continuity in both hoop and axial directions. It is generally preferred for field adjustments and repair work where no other joint systems can be used. This joint is also called butt and strap joint and it results in high strength and requires skilled labor. Once the core pipe is laminated and tested successfully, jacket pipe cut to exact length to fit in the joint area is installed. This jacket pipe piece is laminated with the main jacket pipe by the same procedure. A nozzle is made on the jacket pipe to carry out the air test and subsequent injection of poly urethane foam. This type of joint is applicable for all the available pipe sizes.

|