Above ground installations can be roughly divided into two categories;

a) lines which are laid directly on the surface of the ground

b) lines which are hung or supported as in a typical plant

In case-a, it is anyway advisable to support the pipe by means of wooden or concrete sleepers, in order to avoid pipe damage by stones and other sharp objects.

In nearly all aboveground applications, tensile resistant couplings should be used. Only in case of well supported pipes lines for non-pressure applications a non-tensile resistant system can be used.

Horizontal pipe should be supported at intervals suggested by the support spacing data. Support should be located on plain pipe and not on joints and fittings.

For the supporting of pipe systems, several types of pipe clips can be used. Line contacts and point loads should be avoided, therefore between pipe and steel collar, a support saddle or a protective rubber layer should be provided to minimize abrasion. The minimum width of the saddle should be half the diameter of the pipe.

The clips must fit firmly but must not apply excessive force to the pipe wall. This could result in deformations and excessive wall stresses. The pipe must be allowed to expand within its clamps.

Heavy equipment (pumps, valves etc.) have to be supported independently from the pipe to avoid overloading in both horizontal an vertical directions. In addition to the vertical loads from their weight, valves can have heavy control mechanisms offset from the center of the pipe which can cause bending and torsional loads.

Excessive loading in vertical runs are to be avoided.

Changes of temperature due to operating conditions or ambient, give changes of length and end loading on GRP pipe, which have to be properly manufactured in order to keep values of stress and strain lower then the allowable ones. In case of long pipeline or excessive changes of temperature, expansion loops or expansion joints will be necessary.

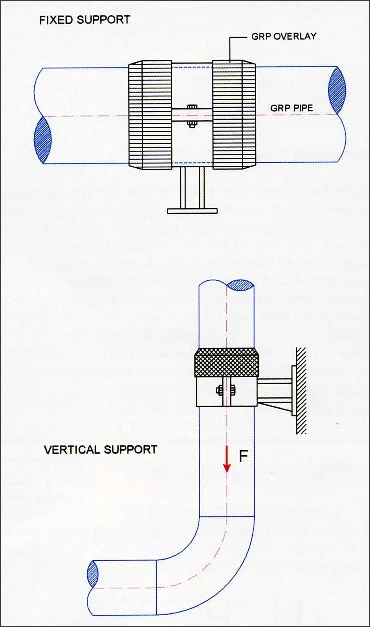

An anchor must positively restrain the movement of the pipe against all applies forces. Anchors can be installed in both horizontal and vertical directions.

Pipe anchors divide a pipe system into sections and must be attached to structural material capable of withstanding any applied forces. In some cases pumps, tanks and other similar equipment function as anchors. Additional anchors are usually located at valves, changes in direction of piping and major branch connection.

When applying unrestrained joints or mechanical couplers, pipe lines must be anchored at each change of direction. Anyway the ation of anchor points shall be determined after a detailed stress analysis.

For securing clamp it is suggested to apply a GRP lamination on each side of the clamp. If the movement of the pipe shall be d only in one direction, it is sufficient to apply just one overlay in the opposite position. Sideways movement is to be prevented by clamping.

If any connections are necessary with machinery or bodies subject to vibrations, such as pumps or other equipment, it is a good engineering practice to avoid a direct link with such systems, because vibrations induce stresses on GRP pipes, which may prevail over the allowable value. A severe condition of vibration occurs when the generating frequency is equal or near the natural frequency of the pipeline. The usual method to avoid vibrations is to install a flexible joint between the source of vibration and the pipe.

ADPF Fiberglass pipes can be made UV resistant by coating poly urethane based epoxy paint or by adding UV stabilizer